Page 84 - Fan Coil Unit

P. 84

FAN COIL UNIT / AIR CONDITIONING

Fan Coil Unit Installation Method - Installation Precautions

Cassette Type/CC

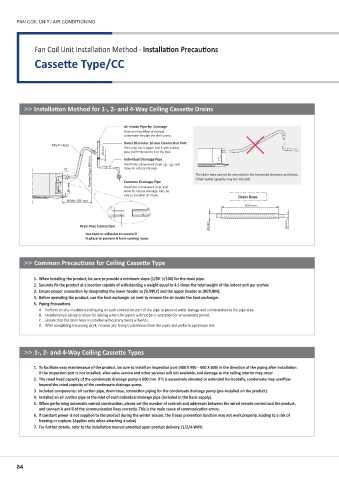

>> Installation Method for 1-, 2- and 4-Way Ceiling Cassette Drains

Air Intake Pipe for Drainage

To prevent backflow of drained

condensate through the drain pump.

Outer Diameter 16 mm Connec�on Port

Drain Hose If the pipe size is larger, seal it with sealing

20 mm tape and firmly secure it to the pipe.

Posi�ve Slope 600 mm The drain hose cannot be extended in the horizontal direc�on as follows.

Individual Drainage Pipe

1

1

–

)

(

80

100

allow for natural drainage.

25 Must have a downward slope and

(Drain pump capacity may be reduced)

180 mm Common Drainage Pipe

Must have a downward slope and

allow for natural drainage. Also, be

sure to install an air intake. Drain Hose

Within 300 mm

600 mm

Drain Pipe Connec�on 23 mm 16 mm

Use tape or adhesive to secure it

in place to prevent it from coming loose.

>> Common Precautions for Ceiling Cassette Type

1. When installing the product, be sure to provide a minimum slope (1/80–1/100) for the drain pipe.

2. Securely fix the product at a location capable of withstanding a weight equal to 4.5 times the total weight of the indoor unit per anchor.

3. Ensure proper connection by designating the lower header as (SUPPLY) and the upper header as (RETURN).

4. Before operating the product, use the heat exchanger air vent to remove the air inside the heat exchanger.

5. Piping Precautions

A. Perform on-site insulation and taping on each connection part of the pipe to prevent water leakage and condensation in the pipe area.

B. Install manual valves to allow for locking when the system will not be in operation for an extended period.

C. Ensure that the drain hose is installed without any twists or bends.

D. After completing the piping work, remove any foreign substances from the pipes and perform a pressure test.

>> 1-, 2- and 4-Way Ceiling Cassette Types

1. To facilitate easy maintenance of the product, be sure to install an inspection port (400 X 400 – 600 X 600) in the direction of the piping after installation.

If the inspection port is not installed, after-sales service and other services will not available, and damage to the ceiling interior may occur.

2. The rated head capacity of the condensate drainage pump is 600 mm. If it is excessively elevated or extended horizontally, condensate may overflow

beyond the rated capacity of the condensate drainage pump.

3. Included components: air suction pipe, drain hose, connection piping for the condensate drainage pump (pre-installed on the product).

4. Installed an air suction pipe at the inlet of each individual drainage pipe (included in the basic supply).

5. When performing automatic control construction, please set the number of controls and addresses between the wired remote control and the product,

and connect A and B of the communication lines correctly. This is the main cause of communication errors.

6. If constant power is not supplied to the product during the winter season, the freeze prevention function may not work properly, leading to a risk of

freezing or rupture. (Applies only when attaching a valve)

7. For further details, refer to the installation manual provided upon product delivery. (1/2/4-WAY)

84