Page 101 - Fan Coil Unit

P. 101

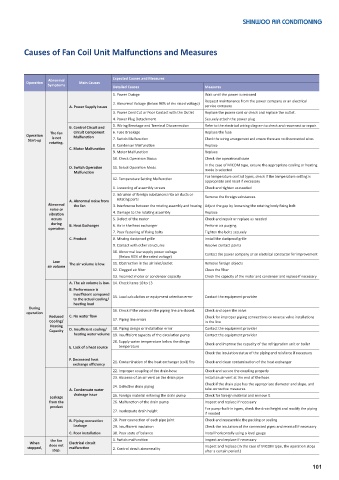

Causes of Fan Coil Unit Malfunctions and Measures of Fan Coil Unit Malfunctions and Measures

Causes

Abnormal Expected Causes and Measures

Operation Main Causes

Symptoms Detailed Causes Measures

1. Power Outage Wait until the power is restored

Request maintenance from the power company or an electrical

2. Abnormal Voltage (Below 90% of the rated voltage)

A. Power Supply Issues service company

3. Power Cord Cut or Poor Contact with the Outlet Replace the power cord or check and replace the outlet.

4. Power Plug Detachment Securely attach the power plug

B. Control Circuit and 5. Wiring Breakage and Terminal Disconnection Refer to the electrical wiring diagram to check and reconnect or repair.

Operation The fan Circuit Component 6. Fuse Breakage Replace the fuse

Malfunction

Start-up is not 7. Switch Malfunction Check the wiring arrangement and ensure there are no disconnected wires

rotating. 8. Condenser Malfunction Replace

C. Motor Malfunction

9. Motor Malfunction Replace

10. Check Operation Status Check the operational state

In the case of MICOM type, ensure the appropriate cooling or heating

D. Switch Operation 11. Select Operation Mode mode is selected

Malfunction

12. Temperature Setting Malfunction For temperature control types, check if the temperature setting is

appropriate and reset if necessary

1. Loosening of assembly screws Check and tighten as needed

2. Intrusion of foreign substances into air ducts or Remove the foreign substances

A. Abnormal noise from rotating parts

Abnormal the fan 3. Interference between the rotating assembly and housing Adjust the gap by loosening the rotating body fixing bolt

noise or

vibration 4. Damage to the rotating assembly Replace

occurs 5. Defect of the motor Check and repair or replace as needed

during B. Heat Exchanger 6. Air in the heat exchanger Perform air purging

operation

7. Poor fastening of fixing bolts Tighten the bolts securely

C. Product 8. Missing dustproof grille Install the dustproof grille

9. Contact with other structures Resolve contact points

10. Abnormal low supply power voltage Contact the power company or an electrical contractor for improvement

(Below 90% of the rated voltage)

Low 11. Obstruction in the air inlet/outlet Remove foreign objects

air volume The air volume is low.

12. Clogged air filter Clean the filter

13. Incorrect motor or condenser capacity Check the capacity of the motor and condenser and replace if necessary

A. The air volume is low. 14. Check items 10 to 13

B. Performance is

insufficient compared 15. Load calculation or equipment selection error Contact the equipment provider

to the actual cooling/

heating load

During

operation 16. Check if the valves in the piping line are closed. Check and open the valve

Reduced C. No water flow Check for improper piping connections or reverse valve installations

Cooling/ 17. Piping line errors in the line

Heating

Capacity D. Insufficient cooling/ 18. Piping design or installation error Contact the equipment provider

heating water volume 19. Insufficient capacity of the circulation pump Contact the equipment provider

20. Supply water temperature below the design Check and improve the capacity of the refrigeration unit or boiler

E. Lack of a heat source temperature

Check the insulation status of the piping and reinforce if necessary

F. Decreased heat

exchange efficiency 21. Contamination of the heat exchanger (coil) fins Check and clean contamination of the heat exchanger

22. Improper coupling of the drain hose Check and secure the coupling properly

23. Absence of an air vent on the drain pipe Install an air vent at the end of the hose

Check if the drain pipe has the appropriate diameter and slope, and

24. Defective drain piping

A. Condensate water take corrective measures

drainage issue 25. Foreign material entering the drain pump Check for foreign material and remove it

Leakage

from the 26. Malfunction of the drain pump Inspect and replace if necessary

product For pump-built-in types, check the drain height and modify the piping

27. Inadequate drain height

if needed

B. Piping connection 28. Poor connection of each pipe joint Check and reassemble the packing or sealing

Leakage 29. Insufficient insulation Check the insulation of the connected pipes and reinstall if necessary

C. Poor installation 30. Poor state of balance Install horizontally using a level gauge

the fan 1. Switch malfunction Inspect and replace if necessary

When Electrical circuit

stopped, does not malfunction 2. Control circuit abnormality Inspect and replace (In the case of MICOM type, the operation stops

stop. after a certain period.)

101